1. Installation precautions

Take preventive measures as much as possible to ensure that the pump is installed in a safe and risk-free manner.

When designing a machine or workshop that requires the installation of the pump, all installation steps must be considered.

Installation design must take into account all installation points, power drive methods, and safety protection devices required by relevant regulations to prevent personal injury.

2. Installation

The connection between the pump and the power unit can be made using pulleys, elastic couplings, or directly through flange connections. The crankshaft can rotate both clockwise and counterclockwise. (Rotate in the direction indicated by the arrow)

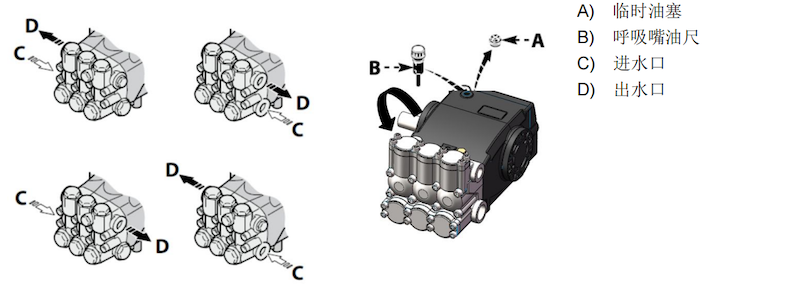

The water supply system needs to be connected to the inlet on the left or right side of the pump (see figure below). Only the pump can be connected to a filtered clean water source. Unscrew the plugs on each port. According to the connection requirements, unused ports should be tightened with bolts.

Before starting the pump, the temporary oil plug (A) used during transportation must be replaced with the accompanying breathing nozzle dipstick (B).

3. Installation and fixation of the pump

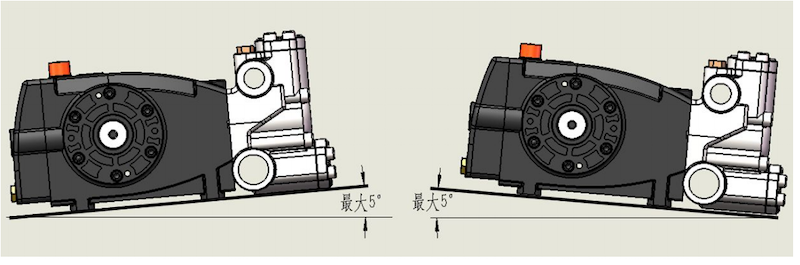

The pump must be installed on a horizontal surface without any unevenness, and there must be no moving parts between the pump and the installation surface. The following figure shows the maximum allowable angle during installation. Beyond this angle, lubrication of the crankshaft system will not be guaranteed. Install screws of appropriate size through the mounting holes on the pump body to secure the pump in place.

4. Connection Guide for Water Supply System

The inlet connection of the pump can be operated according to the following method: Connect to the main water supply pipeline

Connect to the water tank (gravity water supply)

Connect to the booster pump (booster pump water supply)

All connections must meet the following requirements:

1) The inlet connection of the pump must use a pressure resistant hose with a suitable diameter.

2) The hose must be kept unobstructed without any bends or twists.

3) A suitable filter must be installed at the inlet of the pump.

4) All connections between joints and inlet pipes must be sealed to prevent the pump from inhaling air.

5) All water pipes and fittings must match the operating pressure and output flow rate of the pump, and must comply with relevant regulations.

6) To ensure safe operation, it is necessary to select a suitable pressure regulating valve that matches the pump parameters and directly connect the return pipeline to the pump's inlet water supply system.

7) Never connect the return pipe of the high-pressure valve to the inlet pipe of the pump. Be sure to avoid connecting the pressure regulating return pipe directly to the pump's inlet water supply system.

8) Install corresponding pressure reducing devices in the return water system of the pump to minimize the impact damage of water pressure on the water pipes.

5. Connect the main water supply pipeline

The connection of the water supply pipe must be operated in accordance with the recommended specifications:

1) The flow rate of the main water supply pipe system must be twice the normal working flow rate of the pump, with a pressure of 2-3bar

2) Take all the preventive measures described in the 'Water Supply System Connection Guidelines'.

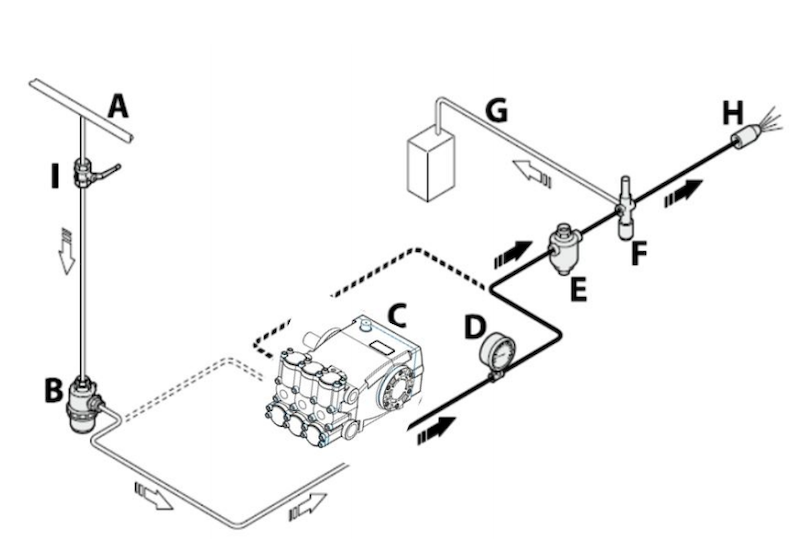

The following is a simple diagram of the connection between the pump and the main water supply pipe.

A) Main water supply pipe B) Inlet filter C) High pressure pump D) Pressure gauge E) Energy storage device F) Pressure regulating valve (return valve) G) Drainage pipe H) Nozzle I) Main water supply pipe switch

Contact: Kelly

Phone: 8613952849807

E-mail: kelly@winfartraffic.com

Whatsapp:8613952849807

Add: GUDONG VILLAGE,SHANGDANG TOWN,DANTU DISTRICT ZHENJIANG CITY,JIANGSU PROVINCE,CHINA.